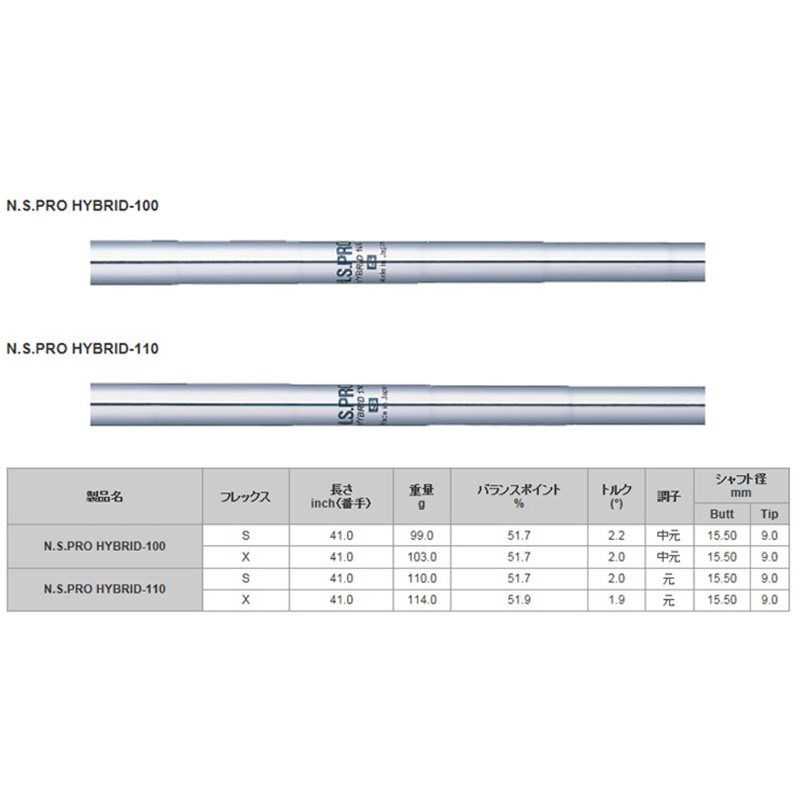

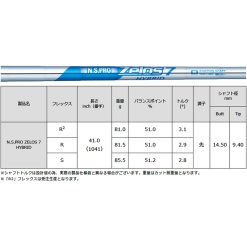

NIPPON SHAFT N.S.PRO HYBRID Series

$25.41

N.S. PRO Modus3 Hybrid

【Advantages of steel and carbon are fused together using patented technology made possible by a comprehensive shaft manufacturer】

In recent years, hybrid clubs have come to be used more and more for layups on tee shots that require distance control and for second shots on long holes, etc. On the other hand, both steel and carbon have their advantages and disadvantages in terms of shafts, and neither has established a reputation. Therefore, as a comprehensive shaft manufacturer with expertise in both steel and carbon, Nihon Shaft began development of a new hybrid shaft with the ability to control trajectory and hit the target.

The key technology was our unique composite shaft manufacturing technology. Our patented special bonding technology enabled the ideal integration of steel and carbon, covering the lack of rigidity of steel alone while at the same time ensuring the high degree of design freedom of carbon. The N.S.PRO MODUS3 HYBRID, an ideal hybrid shaft that eliminates the disadvantages and brings only the advantages, was created by combining the solid feel feedback and spin control performance of steel with the flex control performance of carbon. Graphite On Steel Technology” has been created.

It combines the flight and elevation of carbon with the feel and directionality of steel.

A composite structure of steel and carbon has been achieved in the entire length of the shaft using patented technology.

In order to hybridize the distance performance and ease of a carbon shaft with the feel and spin control performance of a steel shaft at a high level, the ultra-lightweight steel body and carbon laminate are strongly combined with a layer of patented special adhesive technology. N.S.PRO MODUS3 HYBRID Graphite On Steel Technology” achieves unprecedented shaft characteristics with Nihon Shaft’s original manufacturing technology. It is the birth of a completely new option for athlete golfers with a head speed of 44 m/s or higher to maximize the performance of the hybrid club.

A new concept that takes advantage of the merits of steel and carbon and eliminates their demerits.

By compositing steel and carbon with new technology, the thin multi-layer structure of carbon allows for both weight and hardness, while maintaining a solid feel. The new technology also achieves distance performance while ensuring directional stability due to the minimal torsion inherent in steel. Furthermore, the moderate flatness of the shaft due to the thin-wall construction enhances spin control performance, while at the same time allowing the player to feel the thickness of the impact due to the crush return. The steel/carbon hybrid shaft structure is the best solution for hybrid shafts, connecting woods and irons in terms of both function and feel.

| Weight | 2.3 lbs |

|---|---|

| Dimensions | 48 × 4.5 × 2.5 in |

| Shaft | N.S.PRO HYBRID-100, N.S.PRO HYBRID-110 |

| Flex | S, X |